Cable Fault Location Test Case

Client:State Grid Henan Power Company Anyang Power Supply Company

Problem Description:

This test was conducted at the invitation of State Grid Henan Power Company Anyang Power Supply Company. We went to the vicinity of Anyang International Automobile City to locate a faulty 10KV cable. Due to limited handover data, the customer was unable to locate the fault point's position.

Test Date and Duration:2023-4-20,1 hour

Testing equipment:Ronaldo Cable Fault Locator/MRT700 Cable Rout Tracer/CFP-7 Cable Fault Pinpointer/Insulation Resistance Tester/Sports Watch

Testing content:Cable fault location

Testing objectives:Maintenance

Test subject:10KV pole cable (underground, passing under the road to the automobile city, with a ground insulation of 0.3MΩ) - Cable distance: 900m

Test Overview: Using a 2500V megohmmeter, measure the insulation resistance of Phase A to ground as 0 MΩ, Phase B to ground as 0.3 MΩ, and Phase C as normal. Due to the unavailability of a multimeter for retesting low resistance values, the TDR cannot directly view the fault waveform, indicating a high-resistance fault.

Step1:Megger Measurement

Step2:Cable Fault Location

Description: After a 12kV impulse, the cursor was positioned at 161 meters, and the voltage was reduced by 9kV, causing the impulse waveform to disappear. Upon re-adjusting to 12kV for another impulse, the location remained around 161 meters.

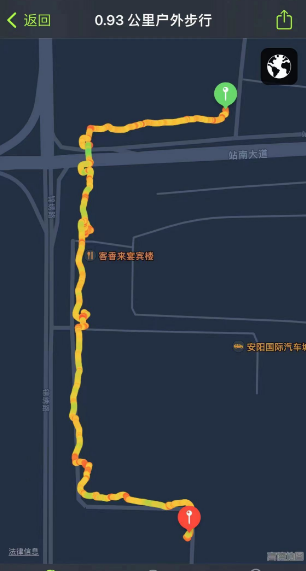

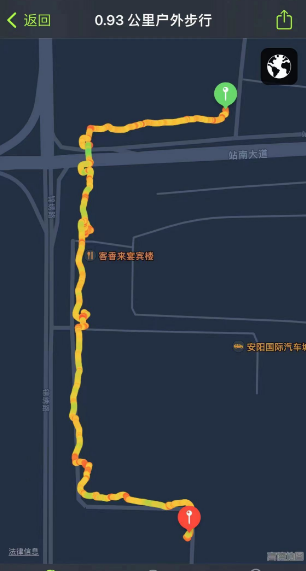

Step3:Cable path location

Description: MRT700 cable path locator, connected directly to the faulty cable via a transmitter. The equipment's receiver is set to AUTO mode, allowing for automatic gain adjustment and cable tracking. The path mapping is as shown in the The fourth figure above.

Step4:Cable Fault pinpoint

Description: The cable fault locator uses the acoustic-magnetic synchronization method to determine the precise location of power cable faults. It generates electronic flashes through an impulse discharge generator, which are picked up and amplified by corresponding probes. By using both auditory and visual cues, the exact position of the fault can be determined. This equipment is used for precise fault location within the rough measurement range of cable faults, combining acoustic-magnetic time difference location technology, noise reduction technology, path-assisted testing, and various testing modes. It provides abundant prompt information and efficiently and accurately locates cable faults.

Based on the total path length and the 161m position, the search is focused in this area. The fault locator is switched to the periodic transmission mode for better audibility. The fault point is locked as being 1.2m directly below the test point. The time delay for precise point measurement is shown in the diagram (noticeable discharge sound can be heard).

Description: The cable fault locator uses the acoustic-magnetic synchronization method to determine the precise location of power cable faults. It generates electronic flashes through an impulse discharge generator, which are picked up and amplified by corresponding probes. By using both auditory and visual cues, the exact position of the fault can be determined. This equipment is used for precise fault location within the rough measurement range of cable faults, combining acoustic-magnetic time difference location technology, noise reduction technology, path-assisted testing, and various testing modes. It provides abundant prompt information and efficiently and accurately locates cable faults.

Based on the total path length and the 161m position, the search is focused in this area. The fault locator is switched to the periodic transmission mode for better audibility. The fault point is locked as being 1.2m directly below the test point. The time delay for precise point measurement is shown in the diagram (noticeable discharge sound can be heard).