Keep Greater Test!Keep Greater Together!

-

- HOME

- PRODUCTS

-

APPLICATIONS

-

Power Detection

- Battery Tester

- Switch

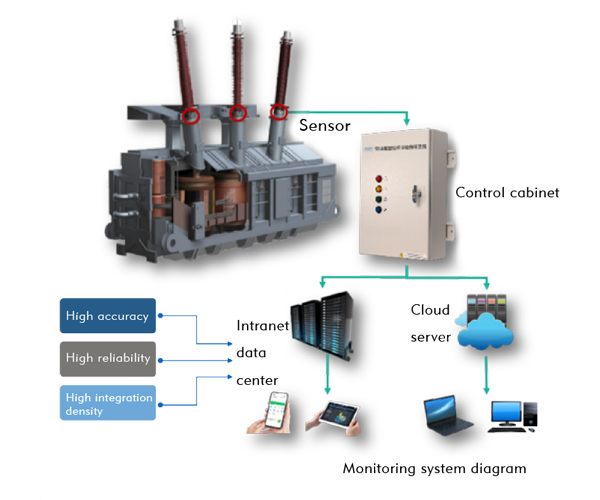

- Switchgear

- Motor

-

Transformer

- Bushing Monitor

- (OTS) Oil Pressure Tester

- (OTD) Oil Dielectric Tester

- (OLTC)On-Load Tap Changer Anal

- Transformer Partial Discharge

- Multifunction Transformer Test

- Sweep Frequency Response Analy

- Transformer Degaussing Tester

- Transformer Ohmmeter

- Transformer Turns Ratio Tester

- Dielectric Frequency Response

- Relay Protection

- Electrical Safety

- Cable

- CBRN

- UAV

- BRANDS

- SERVICES

- ABOUT